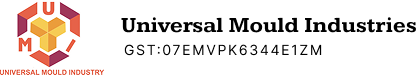

Damru plastic paver block mould

150 INR/Piece

Product Details:

- Shaping Mode Die-Casting

- Material Plastic

- Height 60 Millimeter (mm)

- Product Type PLASTIC

- Mould Life 6 Months

- Color WHITE

- Click to View more

X

Damru plastic paver block mould Price And Quantity

- 50 Piece

- 150 INR/Piece

Damru plastic paver block mould Product Specifications

- 60 Millimeter (mm)

- 6 Months

- PLASTIC

- Plastic

- Die-Casting

- WHITE

Damru plastic paver block mould Trade Information

- Cash Advance (CA), Cash in Advance (CID)

Product Description

| Mould Material | PLASTIC |

| Usage/Application | Construction |

| Color | customized |

| Size/Dimension | customized |

| I Deal In | New Only |

| Country of Origin | Made in India |

UNIVERSAL MOULD INDUSTRY is the leading and renowned name in providing best in class PVC DAMRU PAVER MOULDS

We are the leading SUPPLIER of PVC DAMRU PAVER MOULDS

We are the DEALER of PVC DAMRU PAVER MOULDS

We provide the best quality of PVC DAMRU PAVER MOULDS

We provide the large variety of PVC DAMRU PAVER MOULDS

We deal PAN INDIA

Our well facilitated infrastructural unit enables us to make a highly qualitative PVC DAMRU PAVER MOULDS which is developed by making use of excellent quality components.

With the aid of our trained professionals, we are able to provide an extensive range of CONCRETE MOULD,COLUMN MOULD,ROAD BARRIER MOULD,GARDEN BENCH MOULD,KERB STONE MOULD,TULSI POT,FENCING POLE MOULD,DRAIN MOULD,FIBERGLASS MOULDS,RUBBER MOULD,PAVER TILE MOULDS,CEMENT POLE MOULD,VENTILATION RUBBER MOULD,COMPOUND WALL MOULD,RAILWAY SLEEPER MOULD,COVER BLOCK MOULD,FRP MOULD,ROUND MANHOLE COVER,PAVER MOULD,FLOOR TILE MOULDS,PLASTIC PAVER MOULDS,SILICONE PAVER MOULDS,CONCRETE MIXER,FRP SQUARE MANHOLE COVER, PVC TILE MOULDS,RCC TREE GUARDS,PVC PAVER MOULDS,GARDEN BRIDGE,PVC MOULDS,DOOR FRAME MOULD,Y POLE MOULD,GRASS CONCRETE PAVER,WALL TILE MOULD,COVER BLOCK RUBBER MOULD,PVC MOULDING,BRICK MOULD,CONCRETE TILE MOULDS,INDUSTRIAL RUBBER MOULDS,CHEQUERD TILE MOULDS and many more.

Universal Mould Industry,Certified Company is counted amongst the prominent manufactures of a wide range of Manhole Covers Moulds, RCC and FRP Tree Guard Mould, Drainage Mould, Compound Wall Moulds, RCC and FRP Bench Moulds, Coping Moulds, Boundary Wall Moulds, Door Frame Moulds, Window Frame Moulds, Precast Pole Mould, Road Barrier Moulds, Bollard Moulds, Curb Stone Moulds, Corona Disinfection Tunnel, FRP Pole and more. All our manufactured products are in accordance with global quality standards. Offered products are made by considering only quality approved materials given by the authentic vendors of the market.

Universal Mould Industry,Certified Company is counted amongst the prominent manufactures of a wide range of Manhole Covers Moulds, RCC and FRP Tree Guard Mould, Drainage Mould, Compound Wall Moulds, RCC and FRP Bench Moulds, Coping Moulds, Boundary Wall Moulds, Door Frame Moulds, Window Frame Moulds, Precast Pole Mould, Road Barrier Moulds, Bollard Moulds, Curb Stone Moulds, Corona Disinfection Tunnel, FRP Pole and more. All our manufactured products are in accordance with global quality standards. Offered products are made by considering only quality approved materials given by the authentic vendors of the market.

Universal Mould Industry,Certified Company is counted amongst the prominent manufactures of a wide range of Manhole Covers Moulds, RCC and FRP Tree Guard Mould, Drainage Mould, Compound Wall Moulds, RCC and FRP Bench Moulds, Coping Moulds, Boundary Wall Moulds, Door Frame Moulds, Window Frame Moulds, Precast Pole Mould, Road Barrier Moulds, Bollard Moulds, Curb Stone Moulds, Corona Disinfection Tunnel, FRP Pole and more. All our manufactured products are in accordance with global quality standards. Offered products are made by considering only quality approved materials given by the authentic vendors of the market.

We are the leading SUPPLIER of PVC DAMRU PAVER MOULDS

We are the DEALER of PVC DAMRU PAVER MOULDS

We provide the best quality of PVC DAMRU PAVER MOULDS

We provide the large variety of PVC DAMRU PAVER MOULDS

We deal PAN INDIA

Our well facilitated infrastructural unit enables us to make a highly qualitative PVC DAMRU PAVER MOULDS which is developed by making use of excellent quality components.

With the aid of our trained professionals, we are able to provide an extensive range of CONCRETE MOULD,COLUMN MOULD,ROAD BARRIER MOULD,GARDEN BENCH MOULD,KERB STONE MOULD,TULSI POT,FENCING POLE MOULD,DRAIN MOULD,FIBERGLASS MOULDS,RUBBER MOULD,PAVER TILE MOULDS,CEMENT POLE MOULD,VENTILATION RUBBER MOULD,COMPOUND WALL MOULD,RAILWAY SLEEPER MOULD,COVER BLOCK MOULD,FRP MOULD,ROUND MANHOLE COVER,PAVER MOULD,FLOOR TILE MOULDS,PLASTIC PAVER MOULDS,SILICONE PAVER MOULDS,CONCRETE MIXER,FRP SQUARE MANHOLE COVER, PVC TILE MOULDS,RCC TREE GUARDS,PVC PAVER MOULDS,GARDEN BRIDGE,PVC MOULDS,DOOR FRAME MOULD,Y POLE MOULD,GRASS CONCRETE PAVER,WALL TILE MOULD,COVER BLOCK RUBBER MOULD,PVC MOULDING,BRICK MOULD,CONCRETE TILE MOULDS,INDUSTRIAL RUBBER MOULDS,CHEQUERD TILE MOULDS and many more.

Universal Mould Industry,Certified Company is counted amongst the prominent manufactures of a wide range of Manhole Covers Moulds, RCC and FRP Tree Guard Mould, Drainage Mould, Compound Wall Moulds, RCC and FRP Bench Moulds, Coping Moulds, Boundary Wall Moulds, Door Frame Moulds, Window Frame Moulds, Precast Pole Mould, Road Barrier Moulds, Bollard Moulds, Curb Stone Moulds, Corona Disinfection Tunnel, FRP Pole and more. All our manufactured products are in accordance with global quality standards. Offered products are made by considering only quality approved materials given by the authentic vendors of the market.

Universal Mould Industry,Certified Company is counted amongst the prominent manufactures of a wide range of Manhole Covers Moulds, RCC and FRP Tree Guard Mould, Drainage Mould, Compound Wall Moulds, RCC and FRP Bench Moulds, Coping Moulds, Boundary Wall Moulds, Door Frame Moulds, Window Frame Moulds, Precast Pole Mould, Road Barrier Moulds, Bollard Moulds, Curb Stone Moulds, Corona Disinfection Tunnel, FRP Pole and more. All our manufactured products are in accordance with global quality standards. Offered products are made by considering only quality approved materials given by the authentic vendors of the market.

Universal Mould Industry,Certified Company is counted amongst the prominent manufactures of a wide range of Manhole Covers Moulds, RCC and FRP Tree Guard Mould, Drainage Mould, Compound Wall Moulds, RCC and FRP Bench Moulds, Coping Moulds, Boundary Wall Moulds, Door Frame Moulds, Window Frame Moulds, Precast Pole Mould, Road Barrier Moulds, Bollard Moulds, Curb Stone Moulds, Corona Disinfection Tunnel, FRP Pole and more. All our manufactured products are in accordance with global quality standards. Offered products are made by considering only quality approved materials given by the authentic vendors of the market.

High-Quality Construction Moulds

Our Damru plastic paver block moulds are fabricated from durable plastic materials, providing a dependable option for repetitive and consistent block production. The moulds white color, combined with a 60 mm height specification, ensures it integrates effortlessly into varied project requirements while maintaining shape integrity.

Versatile Application Across Industries

These moulds are versatile, suiting the needs of different stakeholders such as manufacturers, suppliers, traders, and service providers across India. Their adaptability makes them highly desirable for urban infrastructure, garden landscaping, or commercial flooring applications.

FAQs of Damru plastic paver block mould:

Q: How is the Damru plastic paver block mould used in the manufacturing process?

A: The Damru plastic paver block mould is filled with concrete or similar materials in a die-casting process, ensuring each paver block is consistent in shape and size. Once set, the mould is removed, and the paver block is ready for curing and use.Q: What is the typical lifespan of this mould, and can it be extended?

A: This mould typically has a life span of 6 months under normal operating conditions. Its longevity depends on usage frequency and maintenance. Regular cleaning and proper handling can help maximize its service life.Q: When should the mould be replaced for optimal results?

A: You should consider replacing the mould once visible wear, deformities, or reduced block quality are observed, usually after about 6 months or as recommended by your quality inspection routine.Q: Where can this paver block mould be sourced in India?

A: The Damru plastic paver block mould is available across India through an extensive network of distributors, exporters, importers, manufacturers, retailers, service providers, suppliers, traders, and wholesalers.Q: What are the advantages of using a plastic paver block mould?

A: Plastic paver block moulds are lightweight, easy to handle, and provide reliable shaping. They resist corrosion, making them suitable for wet materials, and facilitate high-volume, uniform block production at reduced operational costs.Q: How does the die-casting shaping mode benefit the moulds performance?

A: Die-casting ensures each paver block is formed with consistent dimensions and surface finish, reducing variability and improving the overall appearance and quality of the finished blocks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email